Company Introduction

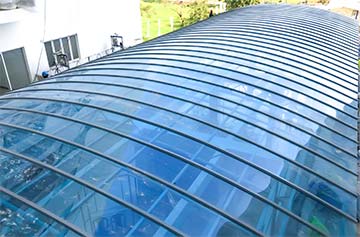

Polyvalley Technology (Tianjin) Co.,Ltd. is located in the Chinese Bohai Sea bay economic center Tianjin city and specializing in R&D, manufacturing and self-exporting of polycarbonate sheets.

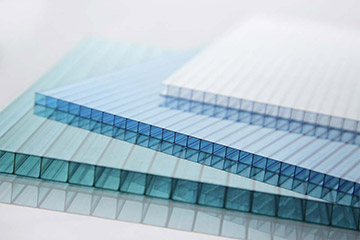

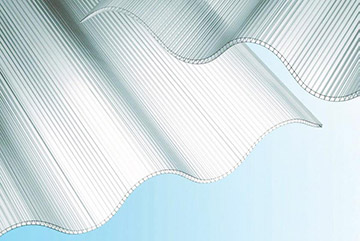

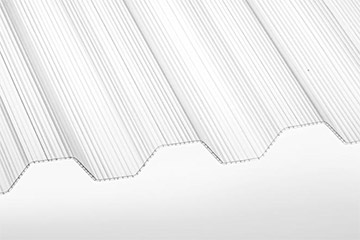

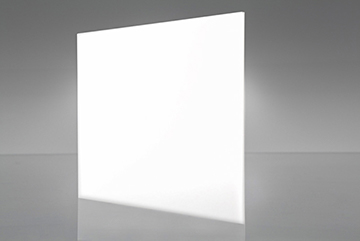

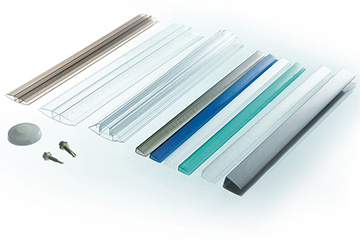

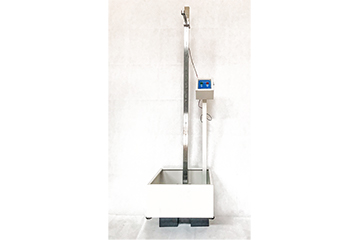

Since its establishment, Polyvalley has focused on the R&D of polycarbonate panels and the manufacturing processes for various high-quality polycarbonate sheets. Polyvalley owns several independent extruding production lines, each with advanced equipment. All of the polycarbonate panels produced by Polyvalley are made from internationally known and respected raw materials, such as those produced by GE and Bayer. Polyvalley products sell well not only in all Chinese provinces, but also overseas, such as in Brazil, the USA, India, Japan, Russia, Italy, etc.

Our promise: As a professional Polycarbonate products manufacturer, we promise that all of our products are made of 100% new BAYER or GE raw material. At least one side has over 50 micro meter UV coating. And we give 10-year quality warranty